PACKING CIGARS IN CIGAR BOXES

A cigar box takes skill to pack. Packing boxes with cigars requires a team effort. The first step is to place a label on each and every cigar. The label is placed on the top quarter of the cigars. An all-natural tree sap glue is used to paste the labels’ ends together around the cigars. Careful attention and concentration by the labeler keeps the cigar’s delicate wrapper from sticking to the label. A mistake can damage the wrapper so training labelers before they actually place the labels is a must. Some train for up to three months before they actually place their first label.

After the labeling, the cigar is individually placed in a cellophane tube. This protects the delicate wrapper as it is transported to the cigar stores and smokes shops, and ultimately to the smoker.

After the cellophane wrapper is placed on the premium cigars, they are hand packed, one by one, into the cedar wood cabinet cigar boxes. The cigar box is specially made to enhance the cigars aging process.

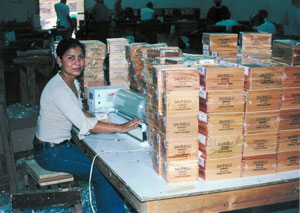

The boxes are then wrapped in cellophane and sealed to protect the precious cigars from the elements during their long journey to the ultimate smoker.

Each cigar box is inspected and packaged in larger boxes. The master box is then moved to the humidified shipping area. Once again the storage area is perfected to keep the cigars in the perfect temperature and humidity.

The cigar’s journey from tobacco seed to a cigar in the smoker’s hand is long and very labor intensive. After you’ve tasted the unique flavors, and smelled the delightful aroma of Tabacalera Esteli cigars, you too will agree that it was well worth the effort to make them the old cuban cigar way.

The cigar’s journey from tobacco seed to a cigar in the smoker’s hand is long and very labor intensive. After you’ve tasted the unique flavors, and smelled the delightful aroma of Tabacalera Esteli cigars, you too will agree that it was well worth the effort to make them the old cuban cigar way.

Return to: